MAXSAFE MANAGE

Most accidents happen due to failure of equipment which could have been prevented if they were inspected on time.

Personal protective equipment(PPE) is a life saving device and mere procurement of PPE for workforce may not help in complete safety for the entire life cycle of the equipment. After investment in PPE , it is important that the user is trained to use it correctly, is aware of periodic maintenance process and gets the equipment inspected periodically..

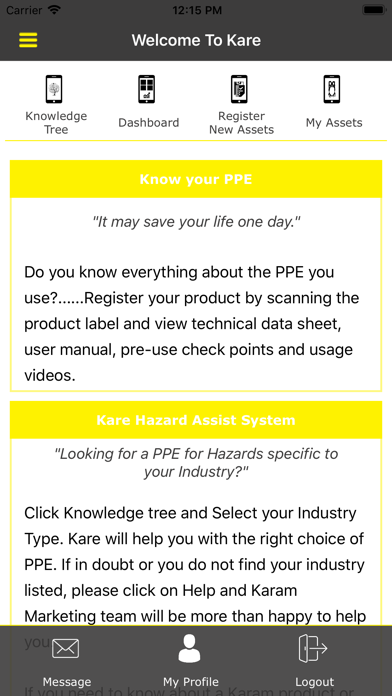

MAXSAFE proudly introduce its Asset Integrity Software MAXSAFE CONNECT, which is a cloud based mobile application that provides a one stop safety solution in creating awareness for the use of safety equipment , inspecting equipment , and performing periodic maintenance .It enhances the life of your equipment and prevents accidents due to failure of safety equipment and machines.

MAXSAFE CONNECT provides an end to end solution to all your safety needs and ensures compliances and accountability of man, machine and safety equipment.

So How does MAXSAFE CONNECT help save costs:-

· Inspects equipment to prevent accidents waiting to happen.

· Performs Periodic maintenance of your machines and saves costs on costly repairs and damage due to malfunction.

· Creates Custom Safety forms Like work permit, HIRA , Method statement ,Incident reporting etc. thus ensuring zero accidents and save huge accident related costs.

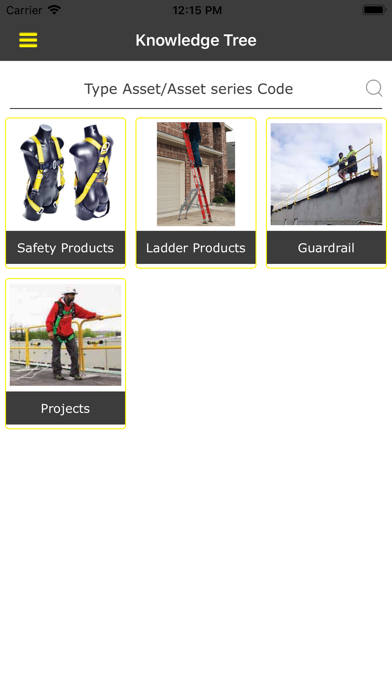

· A robust knowledge tree to make your work force aware of correct usage of equipment ,to avoid accident costs due to ignorance.

· Ensure accountability of your expensive PPE and tools through the Asset management Feature.

· Rope access technicians can log in use hours of their equipment as well as the time they spend on Rope.

Features of MAXSAFE CONNECT

· Inspection in industry involve a mountain of papers which is primary cause of delay in inspection. MAXSAFE CONNECT eliminates the need of paper records .The user can inspect and view reports anytime , anywhere …..all you need is your mobile handset.

· MAXSAFE CONNECT identifies an asset by reading the product label which may have an RFID tag, QR Code , bar code, or a unique identity number ,.It reads them all with your mobile handset without the need of an expensive scanner*

· AIR (annual inspection Reminder) system ,reminds user through a unique traffic light system which turns yellow when inspection is due ,red when overdue and green when inspected.

· The Geo-fencing feature ensures the presence of inspector at site.

· Images captured during each activity provides proof of evidence

· Large numbers of equipment issued to various teams across the organisation may be monitored using the grouping feature, ensuring accountability and making return on investment of equipment positive.

· A dynamic dash board allows the user to view real time status of equipment.

· The messaging system alerts all stake holders of completed activities and non-conformities,

· If you do not have internet coverage, do not worry, KARE works offline as well.

· The safety management system allows safety documentation like work permits, HIRA, Method statements ,incident reporting etc. You can create these reports in your own formats and even add image capture in your reports for proof of evidence.

· RAM (Rope access Management ) is ideal for rope access companies which requires to log in equipment use hours as well as hours the user spend working on ropes.

· Failure of machines in your industry may cause a disaster . Ensure periodic maintenance of your machines with MAXSAFE CONNECT Periodic maintenance feature and get optimum utilization of your machines .

At MAXSAFE we truly believe: –

“Technology saves Precious Human Lives”